Call us: +1 315 791 4196 | Email: info@trayotek.com

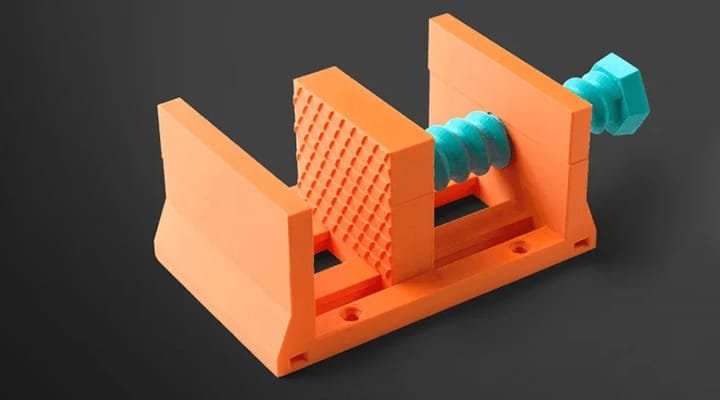

SLS (Selective Laser Sintering) 3D Printing Services

In Selective Laser Sintering (SLS), a laser precisely sinters polymer powder particles, fusing them together layer via layer to create a element. The materials utilized in SLS are thermoplastic polymers in granular form.

During the 3-D printing manner, the SLS system preheats the majority powder material within the powder mattress to simply beneath its melting factor. This preheating makes it simpler for the laser to raise the temperature of the chosen areas to their melting factor. A curler then applies a layer of polymer powder, and the laser sinters the powder in keeping with the three-D version. After every layer is completed, the construct platform lowers, and a new layer of powder is applied. This cycle keeps till the component is fully shaped.

Technical requirements For SLS

- Standard Lead time: Minimum 4 working days depending on part size, number of components, and finishing requirements lead time may increase.

- Standard Accuracy: ± 0.1%

- Layer thickness (resolution): 0.06 mm – 0.15 mm

- Minimum Wall thickness: 1mm

- Max dimensions: 600mm x 600mm x 600 mm. Large parts can be created by assembling individual parts by interlocking designs or gluing them together.

- Surface finishing and Post Processing: Unfinished parts typically have a grainy surface but all kinds of finishes are possible. SLS parts can be sandblasted, smoothed, colored, painted, and coated.

SLA 3D Printing Applications

- Prototypes with good mechanical properties

- Small parts in limited volumes as end-use parts

- Spare parts and complicated art forms

- Lightweight designs

- Architectural models

- Low Volume Production

- Manufacturing prostheses or implants

- Functional parts can be used for drones, robotics, special machinery, and education.

- Personalized manufacturing of unique, complex, designs built as one-off products or in small batches

Suitable Materials for SLS

- Nylon PA12 is a type of polymer powder that has great mechanical properties and chemical resistance. It is ideal for functional parts and prototypes.